Dual vision all-round fully automatic small mounter

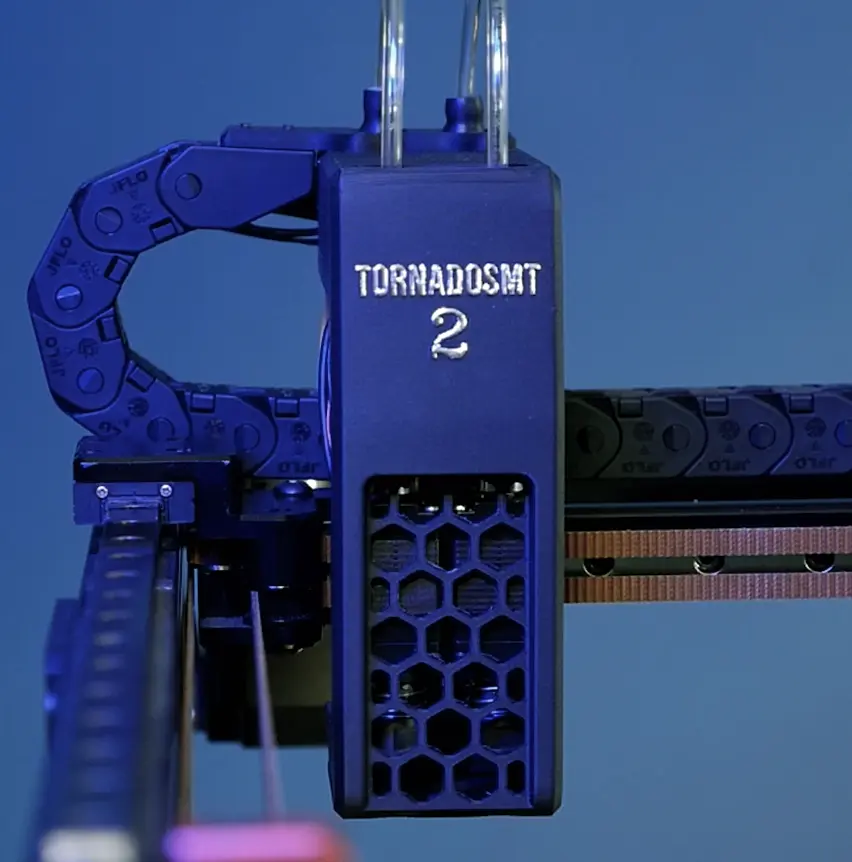

TORNADOSMT 2

CoreXY Structure:

The CoreXY structure is widely used in the field of 3D printing. We boldly brought this technology into the realm of pick-and-place machines and achieved significant success.

This structure allows two relatively heavy XY-axis motors to be mounted on the main frame, greatly reducing the inertia caused by traditional designs where motors must be placed on the movement plane. Additionally, the interaction between the two belts significantly minimizes the impact of belt elasticity, resulting in improved placement accuracy and stability. This enhancement gives us the confidence to handle the placement of 0201-sized components.

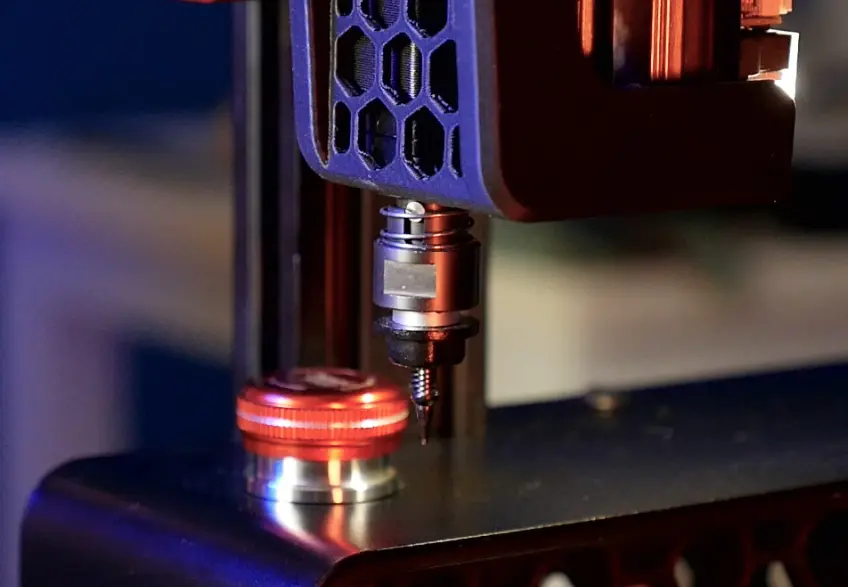

New Vision Camera System

The newly improved vision system features camera firmware exclusively developed for OpenPnP. The bottom camera utilizes a 720P 60FPS global high-speed camera for fast recognition, while the top camera is a 720P 30FPS full-color camera that ensures accurate identification. Most importantly, the new lighting technology eliminates glare and light interference, providing even and soft illumination, significantly improving the success rate of each recognition attempt. This saves time and increases efficiency, especially enhancing recognition accuracy for bulk material trays.

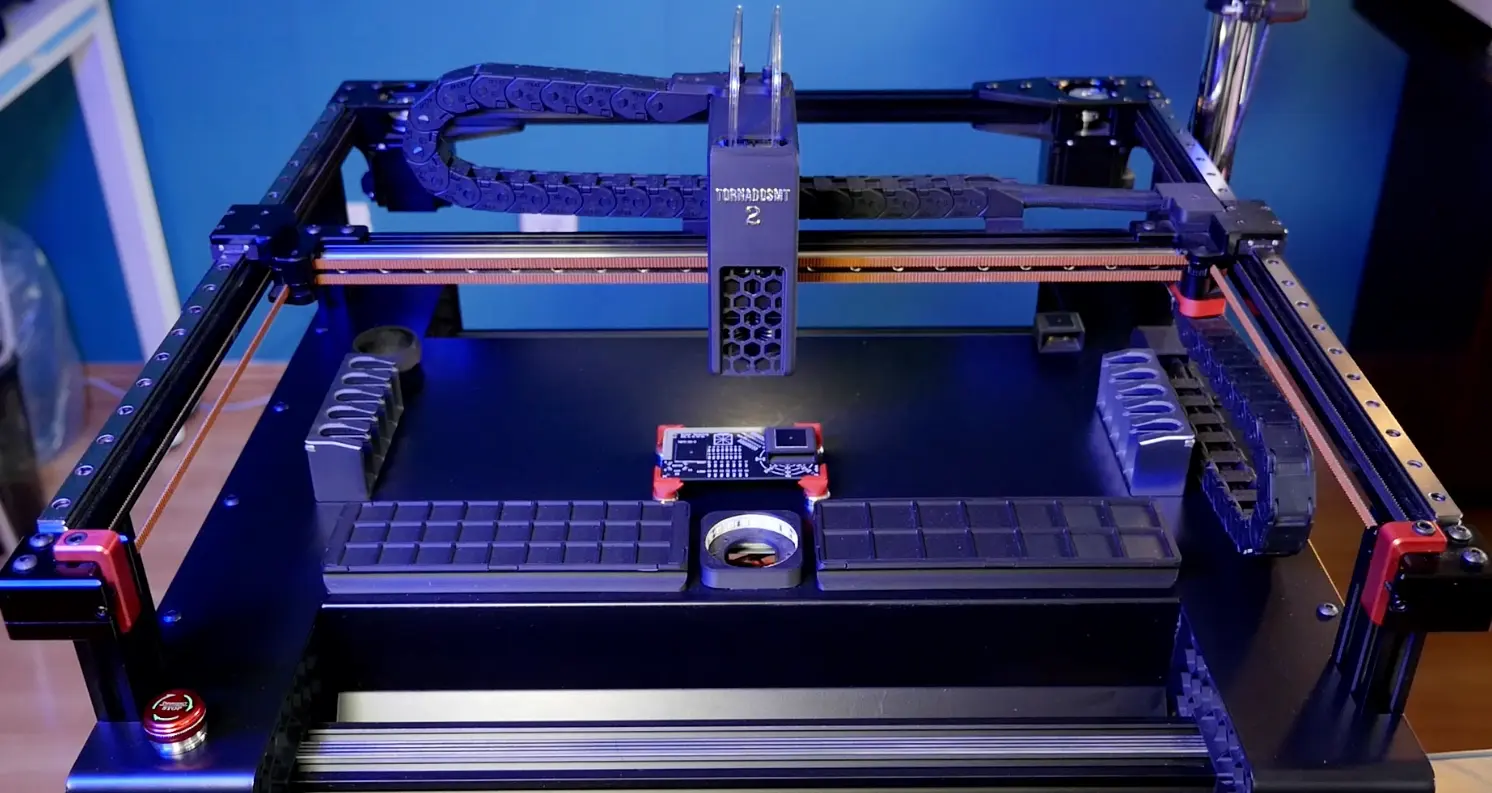

Linear Rail Structure

The machine utilizes a high-precision linear rail design, ensuring accurate and repeatable positioning with every movement. This structure not only enhances the precision and stability of the pick-and-place machine but also significantly reduces wear and deviations over time. Whether during high-speed operations or complex tasks, the high-precision linear rails guarantee smooth performance and outstanding positioning accuracy, ensuring top-tier results in every placement.

Emergency Stop Button

Although rarely used, we have still designed an emergency stop button to ensure that it can be pressed immediately in case of an emergency, safeguarding both personnel and equipment.

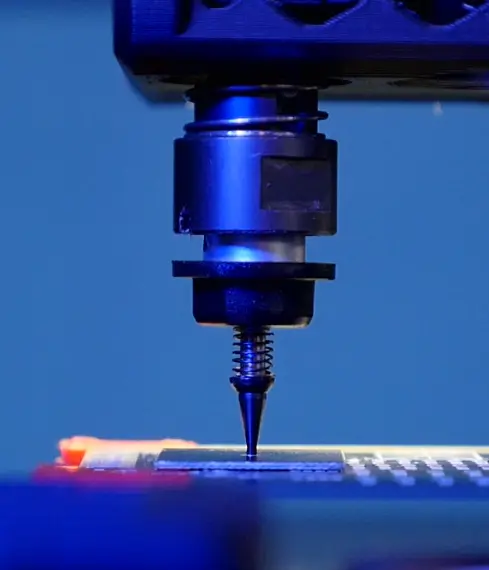

Built-in Vacuum System

There is no need to prepare an external vacuum pump, as the machine comes with a high-suction, high-quality miniature vacuum pump built-in. It is equipped with a custom-designed, high-reliability solenoid valve that ensures continuous operation for 24 hours without overheating or demagnetization. Moreover, it operates without any delays in action, guaranteeing precise, responsive, and accurate performance.

Machine Structure

The machine features 7075 aluminum alloy profiles, with key components precision-machined from 7075 aluminum alloy using high-accuracy CNC processing. This ensures exceptional rigidity and precision. Even during high-speed operation, the machine maintains outstanding accuracy, meeting the requirements of high-performance tasks.

Power Supply

The machine is compatible with both 110V and 220V power inputs, supporting global power standards. It is equipped with a powerful 350W power supply to ensure stable and reliable operation.

Motion Algorithm

The pick-and-place machine features an advanced motion algorithm that optimizes every movement to maintain exceptional precision and stability during high-speed operations. Through intelligent path planning and dynamic adjustments, the system significantly reduces unnecessary pauses and errors, maximizing operational efficiency. The algorithm also effectively balances speed and accuracy, ensuring that every component is placed in the optimal position in the shortest time possible. Whether handling complex mass production or delicate component placements, this motion algorithm guarantees superior performance.

时间内达到最佳位置。无论是应对复杂的批量生产,还是处理精密元件的贴装,该运动算法都能确保卓越的表现。

Magnetic Holder

This magnetic holder allows for flexible placement of PCB boards in any position on the machine’s workbench, optimizing the use of workspace. Additionally, it supports the simultaneous placement of multiple different PCB boards, making it adaptable to various pick-and-place scenarios.

Screw Selection

Our pick-and-place machine exclusively uses 12.9-grade high-strength screws, ensuring exceptional durability and stability even during high-speed operation and extended periods of use. With superior tensile and shear strength, these screws provide enhanced reliability in handling complex placement tasks, reinforcing the overall structural integrity and ensuring precision and safety in every operation.

Weight

Weighing 20kg, this machine differs from traditional factory-grade large pick-and-place machines. By utilizing the ultra-narrow, lightweight placement head design made possible by the CoreXY structure, we achieved a low center of gravity, reducing inertia and enhancing both precision and stability. Despite its lighter weight, the machine still meets high-precision placement requirements and is much easier to transport and install in small studios, labs, and similar settings.

Software Usage

We are committed to providing high-quality desktop pick-and-place solutions and are proud to use the official version of OpenPnP as our system software. During use, we strictly refrain from making any modifications to the OpenPnP software. Even when functionality needs improvement, we adhere to the GPL-3.0 open source license used by OpenPnP, uploading the source code to the official repository to ensure that all improvements are released through official channels. Currently, the Chinese language pack used by OpenPnP is provided by our team, making the software more accessible to a wider range of users. We are also one of the first teams in China to adopt OpenPnP as system software, always at the forefront of open source technology applications. Additionally, we have established and maintain the most comprehensive OpenPnP Chinese community, providing a platform for users to learn, communicate, and receive support, further promoting the adoption and development of OpenPnP in China.

We are the official Chinese language cooperation team of OpenPnP

Help you from concept to finished product - fast realization

Rich functional layout of the countertop

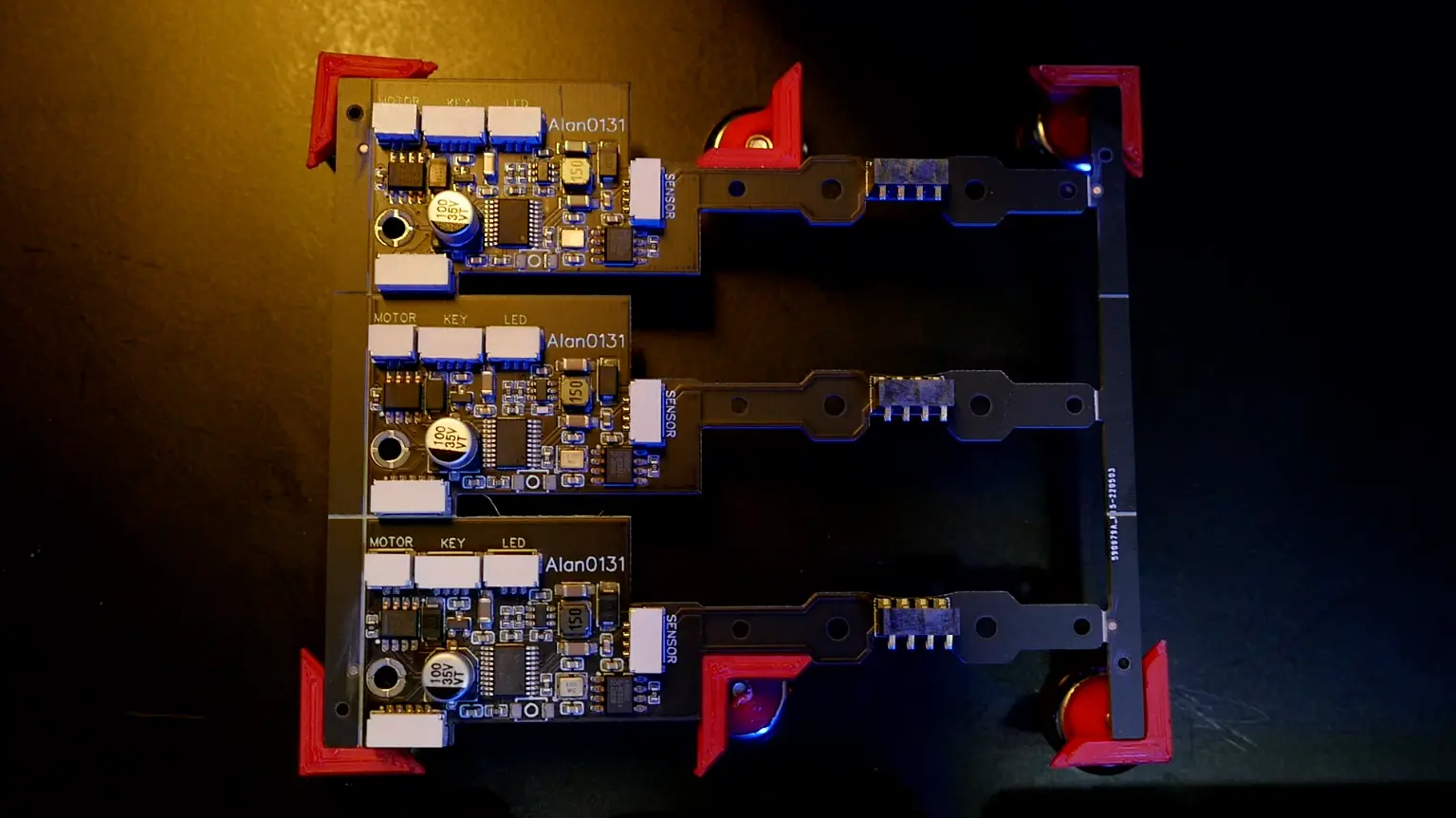

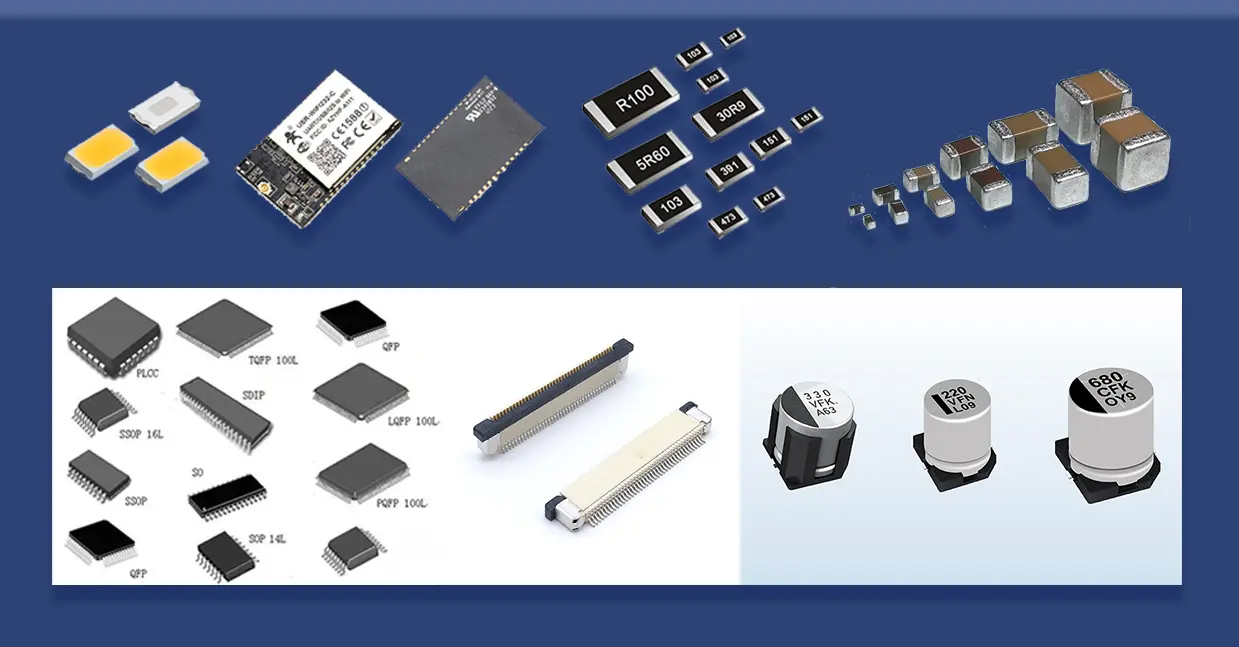

Compatible with mixed mounting of various components

Automatic nozzle replacement

Smooth process

Compatible with all kinds of mounting components

8mm\12mm\16mm\24mm

Meet all your SMD component needs of the above 4 standards