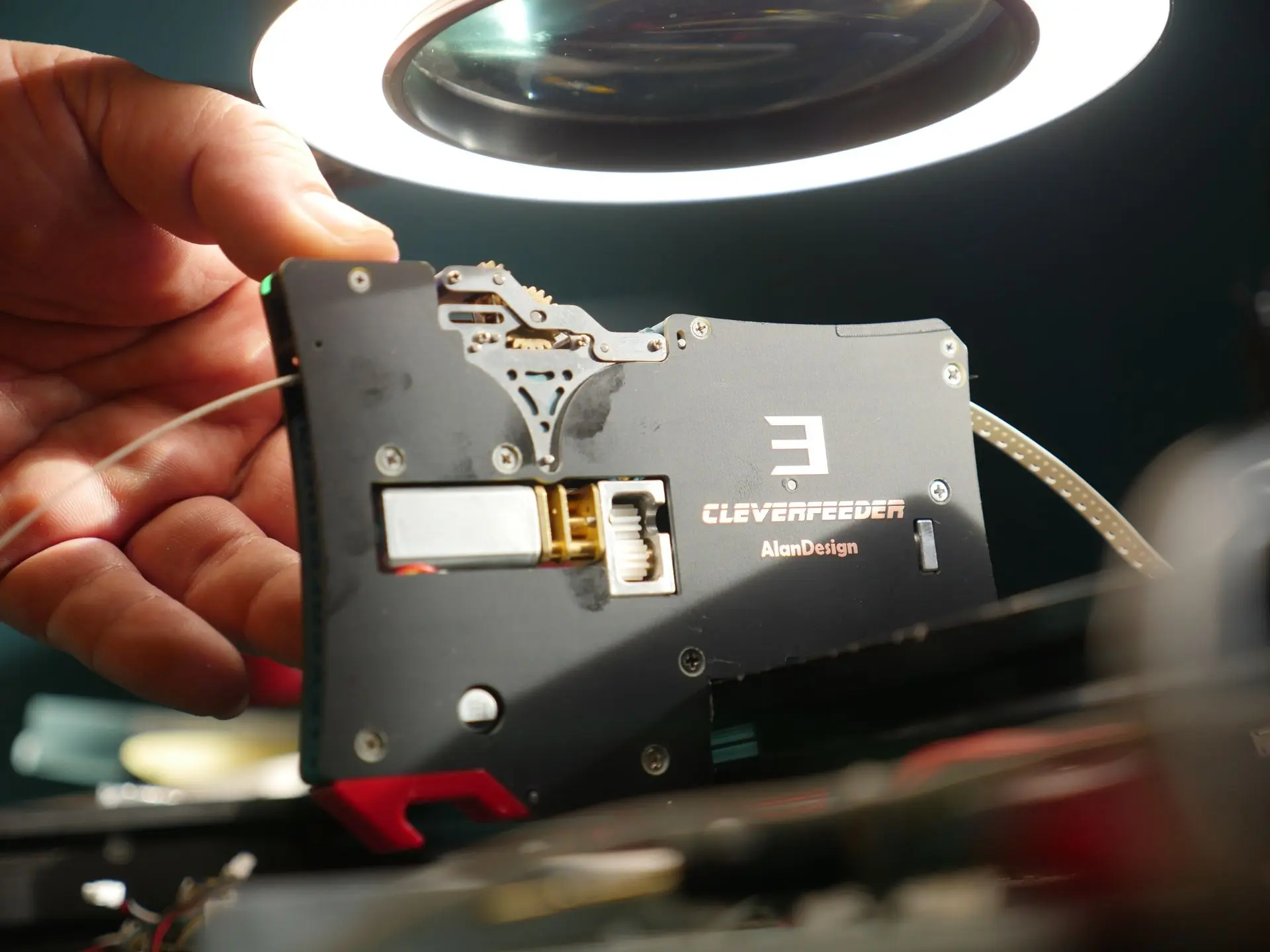

CleverFeeder V3

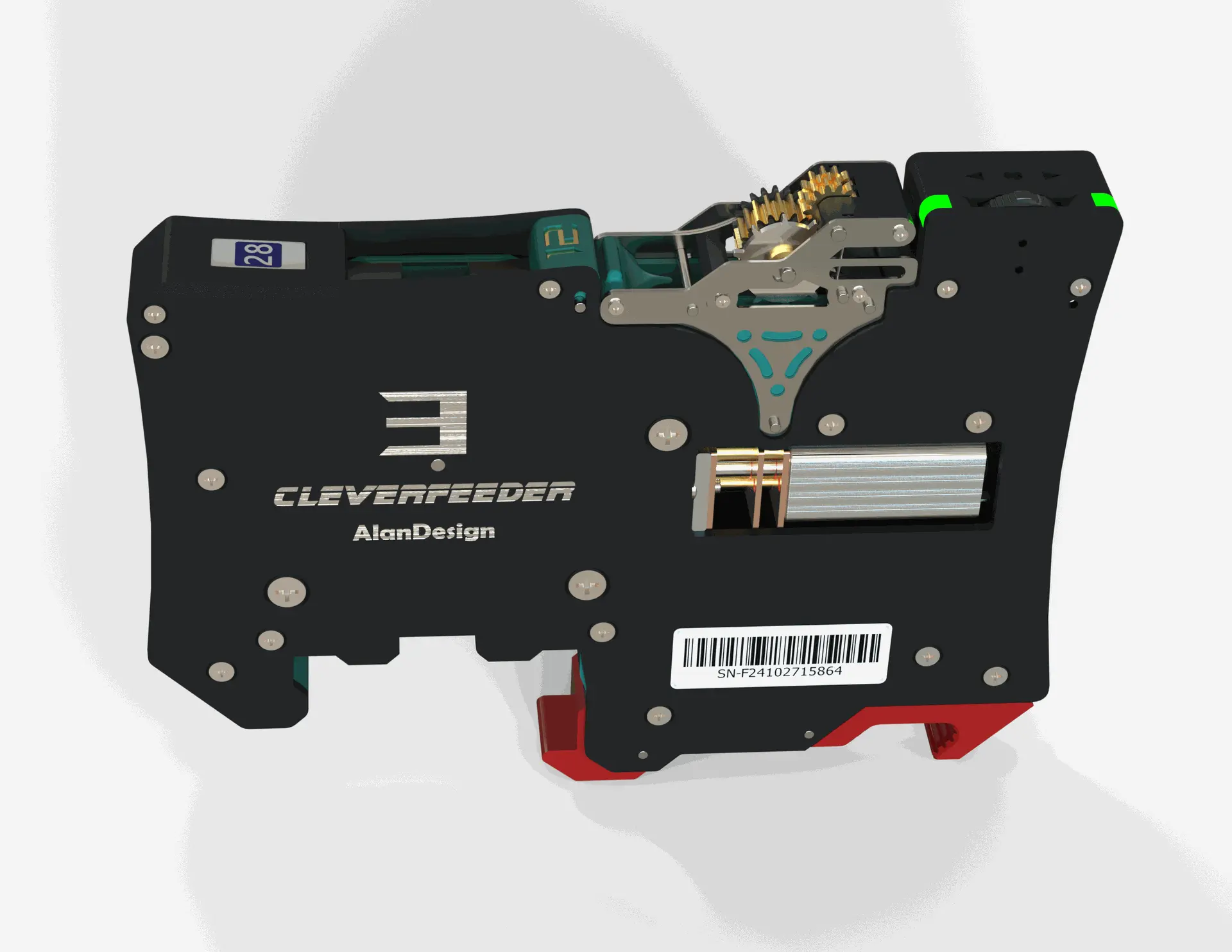

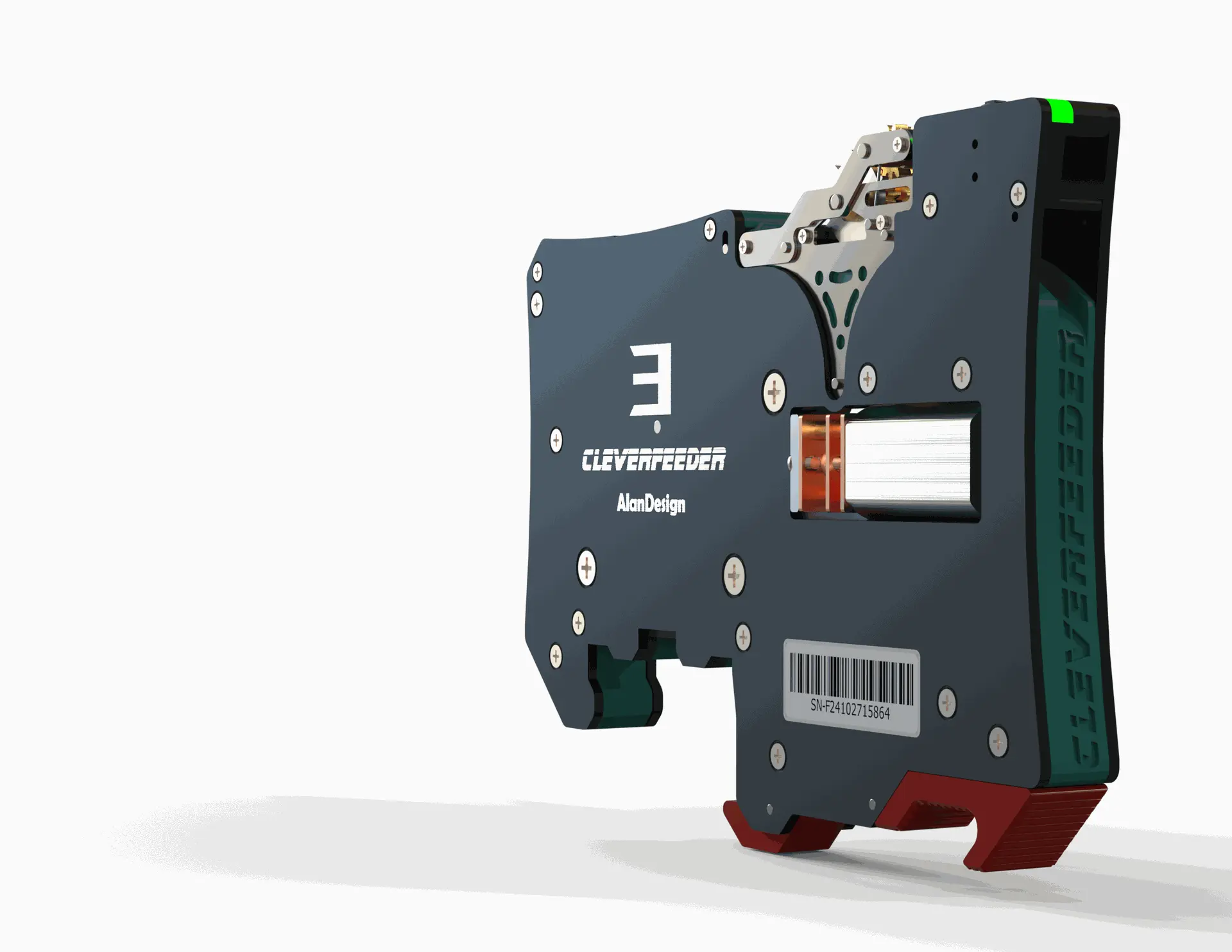

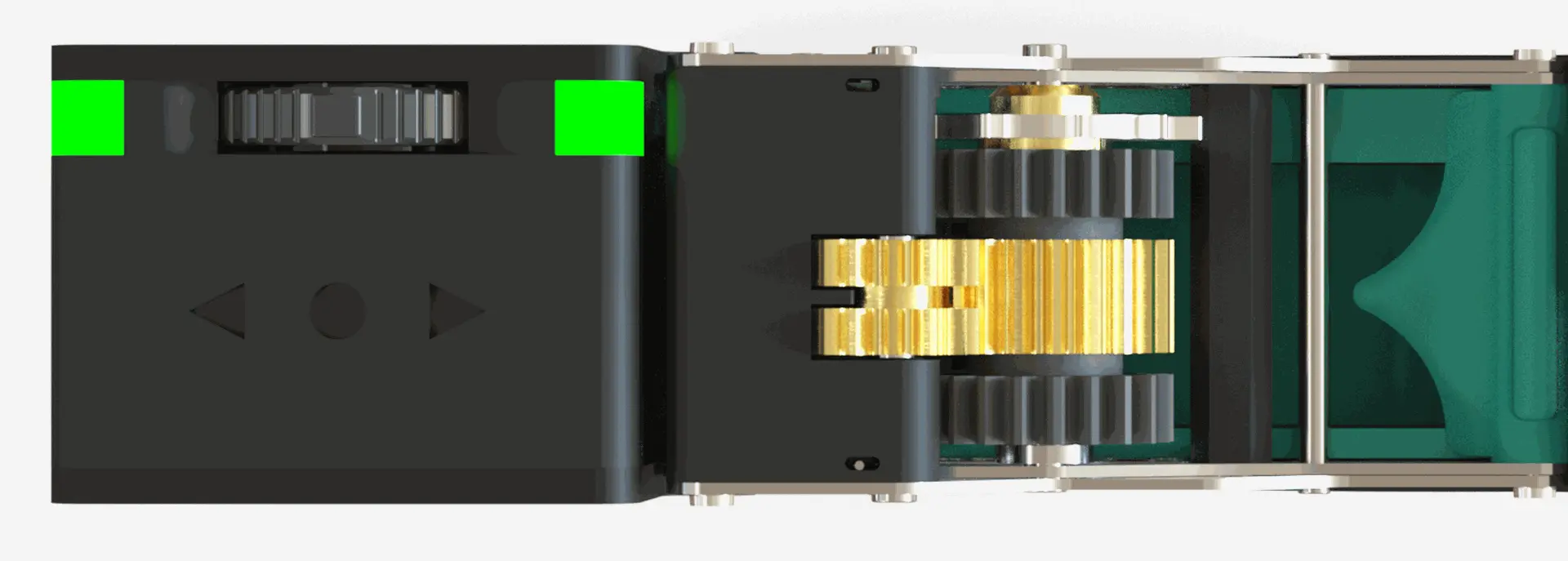

12mm ultra-thin design

The 8mm feeder is only 12mm thin at its thinnest. This means that more feeders can be placed in the same space. For example, 32 CleverFeeders can be placed on one side of the TORNADOSMT V2.

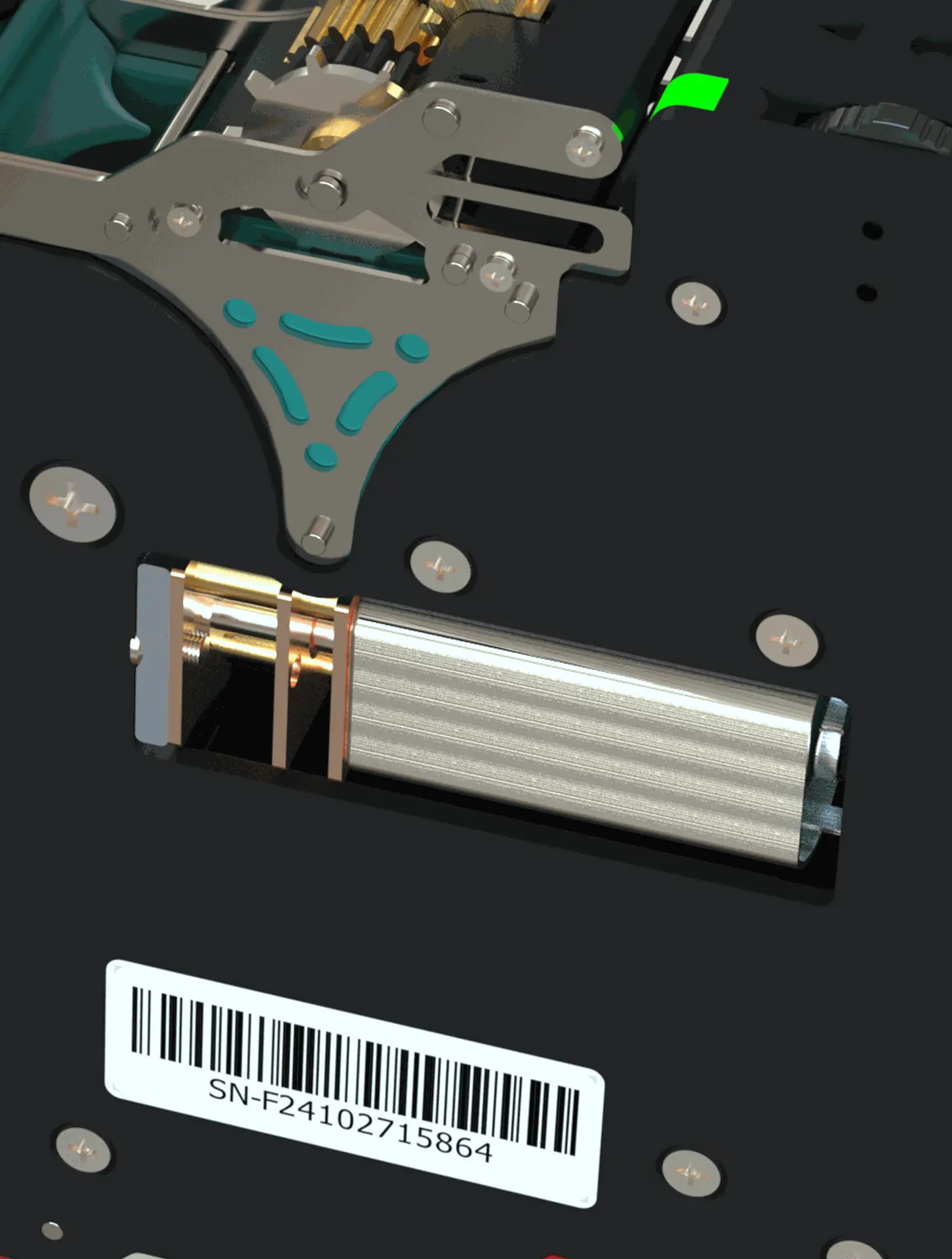

Precision Machining

The core components are made through metal CNC precision processing and high-precision laser cutting technology, which not only ensures excellent performance but also demonstrates extremely high manufacturing precision. The overall performance can be called a work of art.

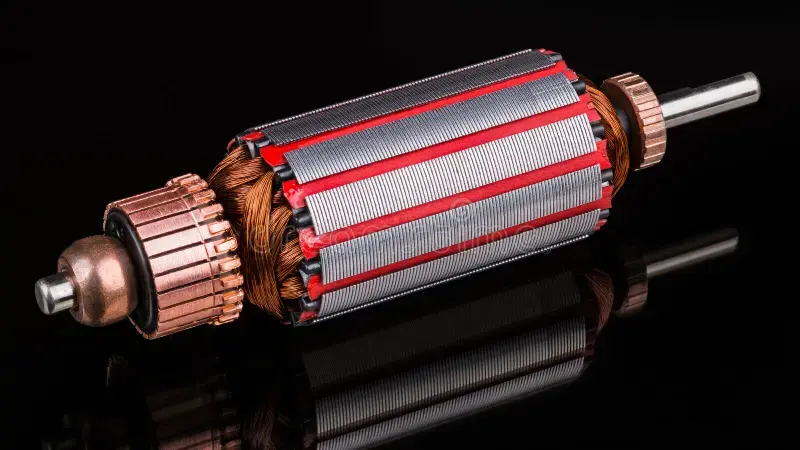

Position Sensors:

The advanced closed-loop control system implemented with a 12-bit magnetic encoder ensures high positioning accuracy and smooth motion curves, effectively avoids material skipping, and provides precise motion performance.

Material feeding and withdrawing control:

Single-point operation can realize single-step feeding or withdrawing. Long pressing for 3 seconds will start the continuous feeding or withdrawing function, which is convenient and quick to change materials.

New structural design:

For the first time, fiberglass board is used as the shell, and the new clip design is used to greatly reduce deformation and ensure that the feeder is stably and securely fixed. The reasonable structural design makes full use of the internal space, making the feeder reach the smallest volume on the market. Compatible with European standard 2040V aluminum alloy profiles as the support seat, equipped with a quick disassembly design, making the opening position easy to touch and more convenient to operate.

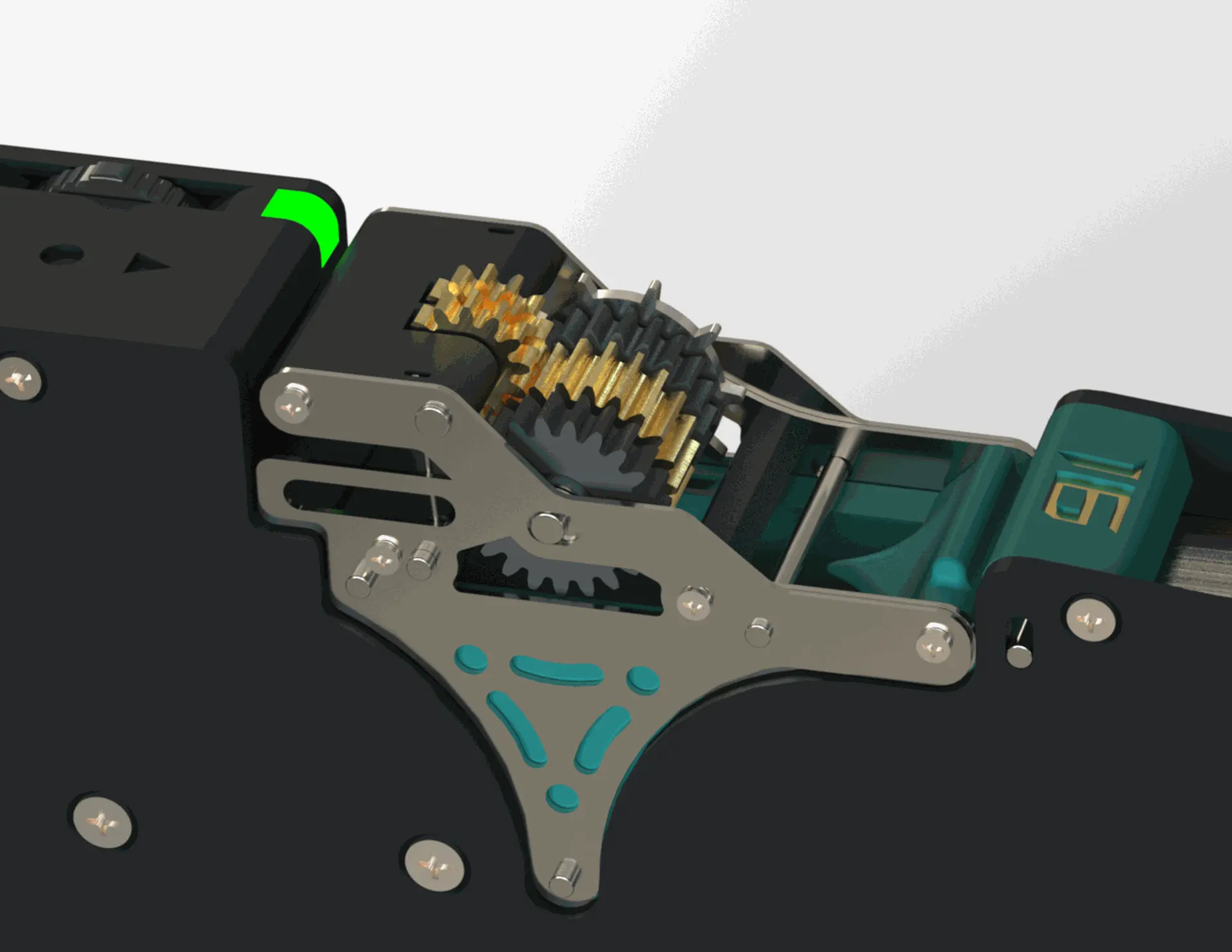

Unique material film separation design:

This material membrane separation technology was inspired by a foreign master XXX. We miniaturized it and combined it with the specially designed "dynamic servo gear gap control" technology to successfully solve this problem and achieve perfect results.

Design of spring material:

The material jumping phenomenon is usually caused by shaking and vibration. In order to solve this problem, we not only optimized the motion curve, but also adopted a uniquely designed physical structure to effectively prevent the occurrence of material jumping and skipping, thereby avoiding frequent shutdowns and ensuring stable and efficient production.

Fully compatible taping design:

With the valuable experience accumulated since the first generation of CleverFeeder was launched, we redesigned the cavity space. The new design not only supports international standard tapes, but also is compatible with non-standard tapes commonly found on the market. The products cover the four most commonly used tape specifications of 8mm, 12mm, 16mm, and 24mm. Even paper tapes with a thickness of 1.3mm (8mm tapes) can pass smoothly. What's more amazing is that the 24mm specification is compatible with tapes with a thickness of up to 11.9mm. No matter what the material is, there is only material you don't need, but there is no material I can't send.

Sealed pressure design:

The internal structure adopts a closed design, which effectively prevents small components such as 0201 or 0402 from falling into the transmission structure and preventing jamming. At the same time, we added nano coating and uniform pressure treatment, which not only reduces resistance but also improves the working efficiency of the motor.

Maximize utilization:

No need to splice tapes, whether it is a whole reel or a small section of tape, it can be effectively used. Even the first and last components can be used normally, avoiding any waste.

Compatible with other brands of placement machines:

CleverFeederV3 is not only seamlessly compatible with TORNADOSMT placement machines, but we have also designed a compatible controller that supports high and low level control and can directly replace traditional pneumatic feeders. It is compatible with placement machines of other brands. The bracket is made of European standard 2040V aluminum alloy profile, which is convenient for upgrading and transformation.

现在已开放预定